My wife got me a billet valve cover for Christmas, and I finally installed it.

I have run into an issue with the CCV.

It has two vents, and one I have connected to a catch can, which is vented to the atmosphere.

The issue comes from filling the catch can with oil within a few miles. I had the same catch can on my stock valve cover without a problem.

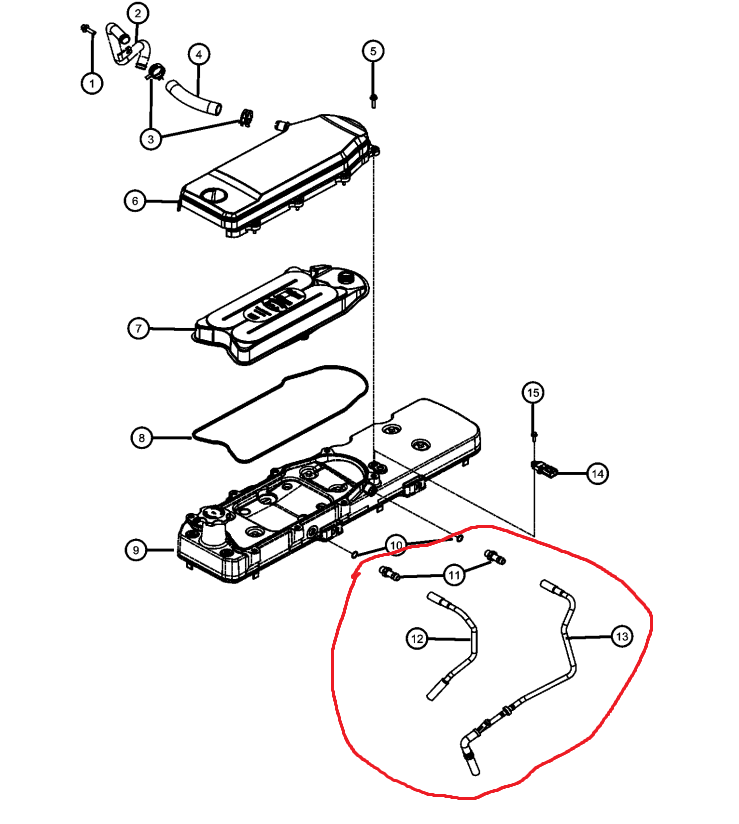

The stock valve cover has two drains leading down to the plate where the old mechanical fuel pump would hook up behind where the PCM sits.

I see other guys just venting to atmosphere without any issues.

I was tempted to drill some ports and install some AN fittings on the side of the billet cover to allow draining to the factory lines.

How does everyone get around this?

There is no excessive blowby.

There is hardly any air that comes out at idle.

This only happens with my billet cover.

Any advice would be appreciated.

Thanks

-Muzzy

The world's #1 resource for everything Cummins Turbo Diesel, with a core focus on supporting every individual in a positive environment, regardless of experience and technical ability.

Please take a second to click here to register, and in a few simple steps you will be able to enjoy a "NO DRAMA" community. Once registered, please introduce yourself.

Thank You.

Please take a second to click here to register, and in a few simple steps you will be able to enjoy a "NO DRAMA" community. Once registered, please introduce yourself.

Thank You.

Thanks:

Thanks:  Likes:

Likes:

Register To Reply

Register To Reply

Bookmarks